Overview

- How to start a LEM Autorun Sequence (LARS)

- Lumps and Bumps - How to prevent major traps with the LEM setup

- LEM Auto Run User Script Interface

- Comment

- Set Needle Valve of the Sample Cryo Transferline

- Set Sample Temperature (Cryos and Oven)

- Set Sample High Voltage

- Set Ring Anode High Voltage

- Load and set a HV transport setting file

- Switches off all the HV's of a chamber

- Open/close BPVX/Y gate valves

- Set Field of the WEW Magnet with the WEWL Magnet Power Supply

- Set Field of the WEW Magnet with the WEWH Magnet Power Supply

- Set Field of the Bpar Magnet with the Danfysik Magnet Power Supply

- Set the field of the sample magnet (WEW or Bpar)

- Set the Spin Rotator Parameters for a given Spin Angle

- Degauss with Danfysik magnet power supply

- Degauss the WEW

- Degauss the sample magnet in place (either WEW or Bpar)

- Degauss the Spin Rotator

- Run Title

- Set the Time of Flight Window

- Set Moderator Info

- Set LEM Setup Info

- Set Waiting Time

- Run Start Command

- Stop an Ongoing Run

- Warm-Up Command

- Loops for Temperature, Sample HV, or Field

- Dump of Raw Sample LakeShore 340 Sensor Data (FOR INTERNAL USE ONLY)

- Floating Ohm Meter (FOM -- FOR INTERNAL USE ONLY)

- Define an alias for the autorun

- Enable/disable autorun midas alarm handling (FOR INTERNAL USE ONLY)

- Enable/disable autorun midas client checking (FOR INTERNAL USE ONLY)

- Define an ODB tag for substitution in the run title

- Set ODB values (FOR INTERNAL USE ONLY)

- Set ODB arrays (FOR INTERNAL USE ONLY)

- LEM Auto Run Sequence Example

- Implementation Details of the LEM Auto Run Sequence

How to start a LEM Autorun Sequence (LARS)

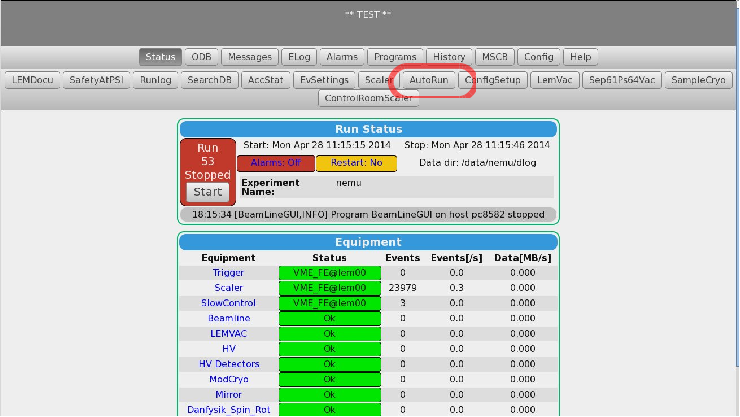

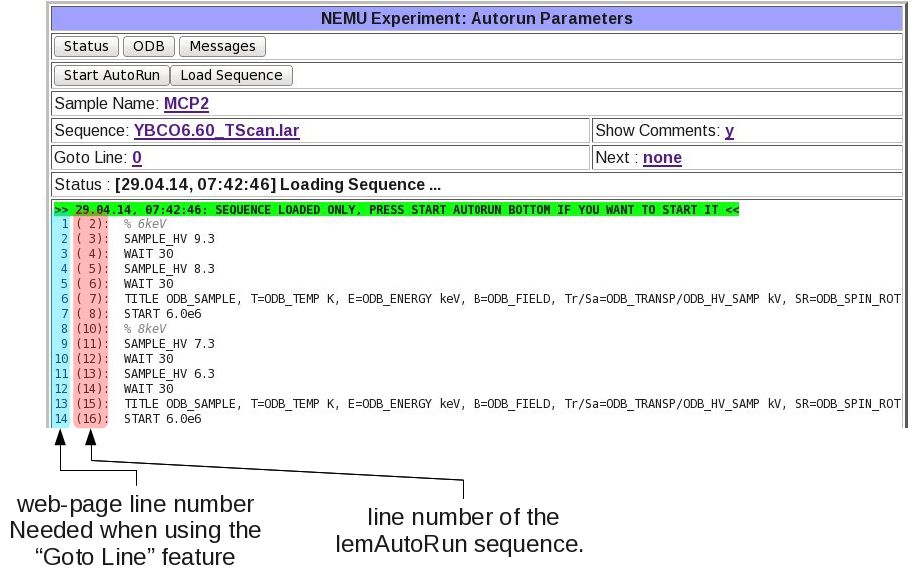

For the moment, there is a very primitive (but simple) user interface for the LEM Autorun Sequence (LARS) foreseen. On the main Nemu Experiment web page, you will find a button called "AutoRun" marked by a red box in the figure above. When pressing it, you will find the LEM Autorun Status web-page which looks like this

- Botton Start AutoRun will try to execute the autorun sequence with the name given in the field Sequence.

- Botton Load Sequence will load the autorun sequence given in the field Sequence. It will not execute the autorun, but only update the web-page.

- Sample Name: shows the sample name which will be written to the file. It can be edited.

- Sequence: here you have to enter the name of your autorun script.

- Show Comments: if set to yes, it will show the comment lines of your autorun sequence. It will only being updated when the autorun is changing to the next command.

- Goto Line: Here can enter a number. This number means that when autorun has finished its current command, rather than executing the next one, it will go to line number you have entered here. This line number should correspond to the "web-page line number" (bluish on the above figure) and not lemAutoRun script number (redish on the above figure).

- Next: here you can enter a lemAutoRun script which shall be executed when to currently running has finished.

- Status: shows the status of the ongoing autorun.

- The next field shows you the ongoing autorun script where the currently executing command is marked in yellow. If there is any severe problem, a red error message will be displayed.

The autorun sequence script has to be saved in the directory /mnt/home/nemu/autoRun. In the field. If the file name's extension is .lar, a high-light plugin for the editor kate is available. This plugin helps to write autorun sequences by high-lighting autorun commands, though it is NOT a syntax are semantic checker!

Lumps and Bumps - How to prevent major traps with the LEM setup

Here some of the major difficulties, concerning lemAutoRun, are described and it is explained how to prevent them.

An autoRun was started, but doesn't execute its first command

In case you have started a run manually, and this run is still active, the autoRun is starting but just waiting (expect the first command is a STOP command see Stop an Ongoing Run and Note of LEM Auto Run User Script Interface) until the current run is stopped.

How to stop an ongoing autoRun, and what are the potential problems arising from stopping it?

To stop an active autoRun see How to start a LEM Autorun Sequence (LARS) Fig. "LEM Autorun Parameter Page". However one has to be aware of the following facts: if the autoRun is stopped during a TEMP command (see Set Sample Temperature (Cryos and Oven)) it might be that the valves BPVX and/or BPVY are closed. Furthermore it might be that the sample HV is set to zero so that is needs to be ramped back by the user.

How to prevent firing the HV interlock while increasing the temperatue?

When increasing the sample temperature with the TEMP command, one needs to be aware of the following problem: while heating, very often the pressure in the sample chamber is increasing. When it is reaching the value of 1e-6mbar, the HV interlock is firing which means that somebody has to reset manually in the area. This pressure can easily being reached while increasing the sample temperature. To prevent this it is wise to use the ramping feature of the TEMP command (see Set Sample Temperature (Cryos and Oven)). Typically a ramping of 1K/min for T<45K, and 2K/min for T>45K is working. This depends not only on the temperature history, but also to some degree on the sample.

LEM Auto Run User Script Interface

The LEM Auto Run User Script Interface consists of a set of simple commands allowing the user to run the LEM experiment for some time, especially during the night. Since the LEM experiment is a rather complicated setup, it should be used circumspectly only. Here the description of the available commands, where the following conventions are used. Anything in squared brackets [] is an option. The syntax is case sensitive.

NOTE:If a run is already underway when starting lemAutoRun, and the first command of the LEM auto run user script is not a STOP command, lemAutoRun will wait until the run is stopped. This is done because it is considered as nonsense to change HV's or temperatures, etc. while a run is underway. Still, the WARMUP command will be executed if the date/time is reached.

Comment

Lines starting with the '' character are comment lines which will be ignored. Furthermore empty lines are ignored.

Set Needle Valve of the Sample Cryo Transferline

with

- pos, the position of the needlve valve (0..100)

- mode, the mode of operation: 0=ReadOnly, 1=Read/Write, 2=Auto

If the mode is set differently than '1', the positional value will be ignored.

Example:

TLF 6.5, 1

Set Sample Temperature (Cryos and Oven)

with

- T, the temperature (in K) of the sample cryo to be set.

- dT, the temperature tolerance band (in K).

- StabilityTimeout, upper limit time constant in which the temperature stability should be achieved (in sec).

- Ramp, demand temperature ramping: 0=off, 0.1-100.0 (K/min). Be very careful with this feature because it might not exactly doing what you think, therefore check also section Implementation of Set Sample Temperature and the Temperature Monitoring during a Run

-

HeaterRange (for 25 Ohm, 1 A)

- 1 -> 2.5 mW

- 2 -> 25 mW

- 3 -> 250 mW

- 4 -> 2.5 W

- 5 -> 25 W

- P, 0 - 1000

- I, 1 - 1000 (1000/sec)

- D, 1 - 1000 (sec)

- Flow, 0 - 32000

Examples:

TEMP 100, 0.1, 1200

TEMP 100, 0.1, 1200, 2.0

TEMP 100, 0.1, 3600, 0.0, , , , , 3200

TEMP 100, 0.1, 3600, 0.0, , 500, 20, 2, 3200

For details concerning the temperature controller flags see the LakeShore 340 Manual.

Description: The Set Sample Temperature takes care of all those adjustments that have to be made, such as closing the vacuumvalves, switching the high voltage, feeding the LakeShore340 with a new setpoint, adjusting the He-flow via the Bronkhorst flow controller and setting the needlevalve in the transferline. Note that the last two items are only possible for the Konti cryostats. The command must give at least the first three parameters. In that case autorun will try to set the new temperature as quickly as possible. With the parameter Ramp the speed of the heating or cooling can be set. If a reasonable rate is demanded (like 1-2 K/minute) no over- or undershoot will occur. WARINING: do not use large rampings while increasing the temperature: there may be problems with the vacuum and thus the high voltage interlock may switch off.

Comments concerning ramping: the ramping rates should not exceed 5K/min, both for cooling are warming up. If you use ramping for cooling the StabilityTimeout constant should be

StabilityTimeout > 120 (Tstart - Tend) / Ramp.

All further parameters inhibit autoRun's automatic adjustments for that parameter. Use of the these options is at the user's discretion and responsibility.

WARNING: Even though lemAutoRun tries to adjust the He flow as good as it can (assuming a closed bypass, so that the Bronkhorst can work), for the lowest temperatures (T < 7K) it might be that you end up with a slightly too high flow when arriving from high temperature. The reason is that the some parts of the cryo are still cooling down at the beginning leading to an increased He flow. When everything is in dynamic equilibrium, lemAutoRun tries to gradually reduce the flow. This process is sometimes too slow and hence the heater might reach its limit. Therefore one should check these temperature range and, if necessary adjust the flow manually with the Bronkhorst flow meter. It is on the To-Do list to fix this little annoyance but we are not there yet :-(

Note: The LS_HeaterMode (name will be changed soon to LS_ControlMode) setting of the device driver has the following meaning (see also the LakeShore 340 Manual chapter 6 p.6-1, and p. 9-28):

- LS_HeaterMode = 1: Manual PID

- LS_HeaterMode = 2: Zone

- LS_HeaterMode = 3: Open Loop

- LS_HeaterMode = 4: Auto Tune PID

- LS_HeaterMode = 5: Auto Tune PI

- LS_HeaterMode = 6: Auto Tune P

By default the value is set to 2, i.e. the Zone Setting Mode. If you do not understand this parameter, set it to 2 if it is not already set to this value.

If LS_HeaterMode = 2, lemAutoRun will, when starting up, overwrite PID's and the heater range to the ZONE setting values. If the TEMP command is explicitly setting PID's and/or heater range, of course this explicit values will be taken. As long as following up temperatures will stay in the same ZONE this PID's and heater range will be taken, except PID's and heater range will be given in the following up TEMP command!

Oven: The TEMP for the Oven is currently a bit limited. It only accepts the following syntax:

with the temperature given in Kelvin!

Set Sample High Voltage

with

- value, the sample high voltage value in (kV).

Examples:

SAMPLE_HV -7.23

Description: Sets the high voltage of the sample. At the moment it is not foreseen to set the sample guard and grid high voltage.

Set Ring Anode High Voltage

- left, HV value of the left ring anode in (kV)

- right, HV value of the right ring anode in (kV)

- top, HV value of the top ring anode in (kV)

- bottom, HV value of the bottom ring anode in (kV)

Example:

RA_HV 11.2, 10.8, 11.0, 11.0

RA_HV 11.2, 10.8

Description: Sets the high voltage of the ring anode. Left and right are defined in beam propagation direction.

Load and set a HV transport setting file

with

- hv_setting_file_name, a HV setting file name

Example:

TRANSPORT_HV fug_07-5kv_2-6ug_SRoff_protons.xml

Description: Loads a HV setting file and sets the found values. Currently only FUG's, i.e. transport HV's can be loaded. The command looks, if the setting file is found in the default location. It also checks if WEW is used, and if the field is > 110.0G will set the RA HV-values to 0.0kV.

Switches off all the HV's of a chamber

with

- chamber, being one of the following tags: MC for the moderator chamber, TC for the trigger chamber, SC for the sample chamber

Example:

HV_OFF SC

Description: switches off the transport and detector HV's of the given chamber.

Open/close BPVX/Y gate valves

Examples:

BPVX open

BPVY 1

BPVY close

Description: allows to open/close the BPVX/Y gate valves. The vaccum control units will prevent this command to work if the pressure on one side is too high, e.g. if the sample chamber would be vented.

Set Field of the WEW Magnet with the WEWL Magnet Power Supply

with

- value, field if unit is given in 'G', otherwise current in 'A'. If no unit is given current is assumed for backward compatibility. Possible range: +-50.0 (A), which corresponds to about +-288 (G).

Examples:

FIELD_WEWL 17.35

FIELD_WEWL 100.0 G

FIELD_WEWL 13.0 A

Description: Sets the field of the WEW magnet, using the high-precision, "low-current" WEWL power supply

Set Field of the WEW Magnet with the WEWH Magnet Power Supply

with

- value, field if unit is given in 'G', otherwise current in 'A'. If no unit is given current is assumed for backward compatibility. Possible range: +-600.0 (A), which corresponds to about +-3400 (G).

Examples:

FIELD_WEWH 17.35

FIELD_WEWH 1500.0 G

FIELD_WEWH 260.3 A

Description: Sets the field of the WEW magnet, using the "high-current" WEWH power supply

Set Field of the Bpar Magnet with the Danfysik Magnet Power Supply

with

- value, field if unit is given in 'G', otherwise current in 'A'. If no unit is given current is assumed for backward compatibility. Possible range: +-20.0 (A), which corresponds to about +-740 (G).

Examples:

FIELD_DANFYSIK 17.2

FIELD_DANFYSIK 100.0 G

FIELD_DANFYSIK 5.3 A

Description: Sets the current for the Danfysik magnet power supply. At the moment you have to give a current but in the near future this will be changed so that the user will enter a field value.

Set the field of the sample magnet (WEW or Bpar)

with

- value, field if unit is given in 'G', otherwise current in 'A'. If no unit is given current is assumed for backward compatibility. Possible range: depends on the magnet WEW or Bpar. See Set Field of the WEW Magnet with the WEWL Magnet Power Supply, Set Field of the WEW Magnet with the WEWH Magnet Power Supply, and Set Field of the Bpar Magnet with the Danfysik Magnet Power Supply .

Example:

FIELD 100 G

Note: The WEW magnet can be operated by either the WEWL or WEWH power supply. The current ranges for these power supplies are: WEWL (+-50A) and WEWH (+-600A). The FIELD command will chose which power supply to be used. For up to +-50A WEWL will be chosen, above 50A the WEWH will be used. There is a potential stumbling block here: in a field scan when crossing the 50A boundary, i.e. switching over from WEWL to WEWH, WEWL will be set to zero, the power supply switched off, WEWH switched on and ramped to the needed current. This means if you have something like

what will happen is 45.0A -> 0.0A -> 55.0A. This could potentially spoil your experiment.

Set the Spin Rotator Parameters for a given Spin Angle

with

- angle, the wished spin angle. 0 degree is parallel to the sample pointing towards the left detector. 90 degree is towards to cryo, -90 degree towards the mirror. When giving a number it will automatically enable the spin rotator.

- ndg, if this flag is set, no degauss procedure will be carried out. Use this option only if you know what you do!

- If off is given, the spin rotator will be disabled, which means switching the spin rotator magnet current off, and shutting down the spin rotator HVs.

Both commands include always an intial degauss procedure of the spin rotator magnet. This way, the user doesn't need to think about the history of the spin rotator magnet.

Examples:

% Separator Mode

SPIN_ROT -10

...

SPIN_ROT off

Degauss with Danfysik magnet power supply

Description: Degauss procedure for the Danfysik magnet power supply. It is first setting -8A, waits 10sec, then set +8A, wait again 10sec, afterward it is cycling the current to -1/2 of its previous value, back and forth. Eventually, if the current value is dropping below 0.1A it will be set to zero.

Degauss the WEW

Description: The degaussing for the WEW (Bperp) setup is doing the following:

- shut down the ring anode (RA) high voltages (HV). This is necessary since for B>110 G (>19 A) a Penning trap forms at the RA which is leading to discharges.

- do the following current cycle of the WEWH: +600/-40/0A, followed by WEWL:+50/-8/0A.

- ramp the RA HV's back to its previous values.

Degauss the sample magnet in place (either WEW or Bpar)

Description: Will call the apropriate degauss routine depending on the sample magnet currently in use (either WEW or Bpar). For details see Degauss with Danfysik magnet power supply and Degauss the WEW .

Degauss the Spin Rotator

Description: Degauss the Spin Rotator. This is done the following way:

- Shut down the spin rotator HV's.

- Set current of the spin rotator magnet to 0A, and wait 10sec.

- Set current of the spin rotator magnet to +12.0A, and wait 30sec.

- Set current of the spin rotator magnet to -1.3A, and wait 30sec.

- Set current of the spin rotator magnet to 0A.

Run Title

with

- string, the run title.

The run title can contain some special tags, in order to extract some useful information directly form the ODB.

- ODB_SAMPLE: sample name tag. Will be replaced by the value from the ODB.

- ODB_TEMP: temperature from the ODB at the beginning of the run.

- ODB_FIELD: field from the ODB at the beginning of the run. This tag will be replaced by a string like "125.60(G)/4.25(A)".

- ODB_TRANSP: HV transport settings from the ODB at the beginning of the run.

- ODB_HV_SAMP: HV sample settings from the ODB at the beginning of the run.

- ODB_ENERGY: implantation energy (HV mod. - HV sample - Energy loss at C-foil) from the ODB at the beginning of the run

- ODB_RA_DIFF_LR: HV difference between left and right RA from the ODB at the beginning of the run i.e. RAL-RAR

- ODB_RA_DIFF_TB: HV difference between top and bottom RA from the ODB at the beginning of the run i.e. RAT-RAB

- ODB_SPIN_ROT: muon spin rotation angle, or disabled if the spin rotator is off.

Furthermore, the user can define his/her own ODB tags via the autorun command ODB_TAG (see Define an ODB tag for substitution in the run title).

Examples:

TITLE Proximity Al-Nb

TITLE Proximity ODB_SAMPLE

TITLE Proximity ODB_SAMPLE T=ODB_TEMP (K)

TITLE Proximity ODB_SAMPLE T=ODB_TEMP (K), ODB_TRANSP (kV), RAL-RAR=ODB_RA_DIFF_LR (kV), B_par ~ ODB_FIELD, Sample = ODB_HV_SAMP (kV)

Description: Sets the run title. Midas handles run titles with a maximal length of 132 characters. If the given run title is longer than this 132 characters, the run title will be truncated to the allowed length.

Set the Time of Flight Window

with:

- start, start of the time of flight window in (TDC channels)

- stop, end of the time of flight window in (TDC channels)

Examples:

TOF 1350, 1785

Description: Used to set the muon time of flight cut.

Set Moderator Info

with,

- mod, moderator

- date, date at which the moderator was grown

Examples:

MODERATOR N2, 19-Dec-2005, 18:00

Description: Sets the moderator information.

Set LEM Setup Info

with,

- string, informations about the setup

Examples:

LEM_SETUP B_par

Description: Sets the information about the experiment setup. It is not necessary to enter which cryostat is used since this is already set in the ODB.

Set Waiting Time

with,

- waittime, waiting time in (sec)

Examples:

WAIT 240

Description: Sets a waiting time. This wait time command is an approximate timing since it checks various things while waiting (flow, system state, etc.), hence the time accuracy is about 3 secs only.

Run Start Command

with,

- no_events, number of events to be taken

- time sec, time to elapse to case a run stop

Examples:

START 1e7

START 1000000

START 120 sec

Description: Starts a run and will collect no_events data. It is taking the title from the ODB at run start, hence preceding to the START command there should be (in almost all cases) the TITLE command.

The second option starts a run and collects data for time seconds. This is typically needed for beam calibration measurements, etc. Currently the only units supported is 'sec'.

Stop an Ongoing Run

with,

- no_events, number of events to be taken

- time sec, time to elapse to case a run stop

Description: This command makes only sense as the first statement of an autorun sequence. It's purpose is that often one is encountering the situation where everything is setup. One has started a run to see if everything is fine, yet one is very tired and the necessary statistics is not achieved. Instead of stopping the run and starting an auto-run sequence, one can use this command, i.e. starting the auto-run sequence with the STOP command. It just accumulates the necessary statistics of the current run before going over to the next command.

The second option will stop the ongoing run after time seconds. Currently the only units supported is 'sec'.

Note: In case an autorun starts accidentally with a STOP command and there is NO ongoing run, lemAutoRun will automatically change the STOP into a START command.

Warm-Up Command

with,

-

date in the format

yyyy-mm-dd -

time in the format

hh:MM:ss

Example:

WARMUP 2007-01-01, 05:00:00

Note: This command can occur in the autorun sequence wherever you want to place it, at the beginning, the end ... The autorun handler checks as a first thing if this command is present and sets it up, hence it is independent of the sequence structure. If it occurs more than once (which is quite stupid by the way) it will take only the first occurring one ignoring the others.

WARNING: This commmand will NOT work properly when the He bypass is open (meaning the bronkhorst He flow controller is bypassed), since in this situation there is no way to reduce the flow by software. So PLEASE, keep this in mind.

Description: Imaging the following situation: You want the change a sample at around 7:30AM. Without this command it would mean that you have to stop any autorun at around 6:00AM, shutdown the HV's, close the BPVX/Y, and start warming up the sample cryostat. Since sleep is precious, this command has been introduced. It does the warming up of the sample cryo according to the just described procedure. A few comments are necessary though: (i) The date-time given in the command is an approximate one in the sense that it will only execute after the current command has been carried out, except for an ongoing run which will be stopped. (ii) What is not under computer controll is the venting procedure for the sample chamber, i.e. it is not possible to let any exchange gas into the sample chamber automatically (and perhaps it is better that way).

Loops for Temperature, Sample HV, or Field

It is possible to set some primitive loops for setting the sample temperature, high voltage or field. The syntax is

The loop MUST consist of at least the following elements in the order given in the code example:

- LOOP_START, loop start tag

- LOOP_LIST or LOOP_ITER, this gives the elements over which to loop

- LOOP_TEMP LOOP_ELEMENT or LOOP_SAMPLE_HV LOOP_ELEMENT or LOOP_FIELD_WEWL LOOP_ELEMENT or LOOP_FIELD_WEWH LOOP_ELEMENT or LOOP_FIELD_DANFYSIK LOOP_ELEMENT or LOOP_FIELD, this is the main loop command. They cannot be combined within the same loop.

- LOOP_END, loop end tag

It is possible to loop over a list of elements (LOOP_LIST). The elements v1, v2 etc. is just a list of elements.

It is also possible to have equidistant sampling points, like in an ordinary for-loop with the LOOP_ITERATOR.

Description: The implementation of loops is there for convenience, allowing one to write more compact autorun sequences. Internally the loops are expanded into a sequence of commands.

Dump of Raw Sample LakeShore 340 Sensor Data (FOR INTERNAL USE ONLY)

with,

- no_dumps, number of sensor dumps to be taken

Description: The dump command writes (appends) 10 time with intervals of about 6 seconds the time, temperature, pressure, heater value and range, setpoint, flow and the 10 raw voltages of the LakeShore340 channels to a file, named: .RawVoltageOutput.dat. This command is useful for thermometer calibrations.

Once per run, a header is added (needed by the calibration software and also useful such that the file is self-explanatory) which will look similar like this

%-------------------------------------------------------------------------- % Number of Entries : 23 % Number of Raw Data Reading : 10 % First Raw Data Reading Entry : 14 % Entry 1 : month % Entry 2 : day % Entry 3 : year % Entry 4 : hour % Entry 5 : minutes % Entry 6 : seconds % Entry 7 : msec % Entry 8 : measured temperature of control channel = A % Entry 9 : pressure % Entry 10 : heater output % Entry 11 : setpoint temperature % Entry 12 : heater range % Entry 13 : BH1 flow measured % Entry 14 : Raw Data Reading Entry 0 : Channel A : Sensor Type 1 % Entry 15 : Raw Data Reading Entry 1 : Channel B : Sensor Type 1 % Entry 16 : Raw Data Reading Entry 2 : Channel C1 : Sensor Type 2 % Entry 17 : Raw Data Reading Entry 3 : Channel D1 : Sensor Type 1 % Entry 18 : Raw Data Reading Entry 4 : Channel D2 : Sensor Type 1 % Entry 19 : Raw Data Reading Entry 5 : Channel D3 : Sensor Type 1 % Entry 20 : Raw Data Reading Entry 6 : Channel D4 : Sensor Type 1 % Entry 21 : Raw Data Reading Entry 7 : Channel C2 : Sensor Type 1 % Entry 22 : Raw Data Reading Entry 8 : Channel C3 : Sensor Type 1 % Entry 23 : Raw Data Reading Entry 9 : Channel C4 : Sensor Type 1 %--------------------------------------------------------------------------

Floating Ohm Meter (FOM -- FOR INTERNAL USE ONLY)

with,

- current, current value of the constant current source in (uA), ranging from -1000.0(uA) to +1000.0(uA).

Examples:

FOM +10.0

FOM -3.25

Description: The FOM is a device built at electronic department of the University of Fribourg (after initial input from Alan Drew (Uni Fribourg) and Andreas Suter (PSI)) and currently not always available.

Define an alias for the autorun

where key is the alias key, and value the corresponding value.

Examples:

ALIAS LED_IN /Equipment/K2400/Variables/Input

ALIAS LED_OUT_ONOFF /Equipment/K2400/Variables/Output[1]

ALIAS LED_OUT /Equipment/K2400/Variables/Output

ALIAS Leff "/Info/t0_Parameter/Leff RAon (mm)"

Description: Alias has been introduced to ease the writting autorun scripts when using ODB_SET_DATA or ODB_SET_DATA_ARRAY commands. It allows to introduce alias tags which at run-time will be replaced by its values. For instance the aliases defined in the examples could hence be us in a command like:

ODB_SET_DATA LED_IN[5], 1e-6, LED_OUT[3], 60, 1e-7

i.e. less sources of typo errors.

Enable/disable autorun midas alarm handling (FOR INTERNAL USE ONLY)

where tag is one of the following: yes | no | true | false | 1 | 0

Description: allows to temporarily ignore midas alarms from within the autorun. The default behavior of the autorun is that the autorun stops as soon as there is a midas alarm. When setting IGNORE_ALARM to 'yes' in the autorun, autorun will just proceed even if an alarm has been encountered.

Examples:

IGNORE_ALARMS no

IGNORE_ALARMS 1

Enable/disable autorun midas client checking (FOR INTERNAL USE ONLY)

where tag is one of the following: yes | no | true | false | 1 | 0

Description: allows to temporarily suppress autorun to check if the necessary clients are running. The default behavior of the autorun is that the autorun stops if not all necessary clients for uSR experiments are running. When set to 'yes' no client checks are performed. This can be useful for some specific tests.

Examples:

IGNORE_CLIENTS yes

IGNORE_CLIENTS 0

Define an ODB tag for substitution in the run title

with,

- odb_path, ODB path to the variable to be used.

- index, index of the variable of an ODB array. If index is omitted, it is assumed that odb_path is a single value.

Description: allows to define tags which will be substiuted in the run title at run time. See also the run title command Run Title.

Examples:

ODB_TAG ODB_P /Equipment/LEMVAC/Variables/Input[11]

TITLE ODB_SAMPLE, T=ODB_TEMP K, E=ODB_ENERGY keV, B=ODB_FIELD, Tr/Sa=ODB_TRANSP/ODB_HV_SAMP kV, SR=ODB_SPIN_ROT, pSC=ODB_P (mbar)

ODB_TAG ODB_LHe /Equipment/LHeLevelMeter/Variables/Input

TITLE ODB_SAMPLE, T=ODB_TEMP K, E=ODB_ENERGY keV, B=ODB_FIELD, Tr/Sa=ODB_TRANSP/ODB_HV_SAMP kV, SR=ODB_SPIN_ROT, LHe=ODB_LHe (%)

Set ODB values (FOR INTERNAL USE ONLY)

with,

- odb_set_key_path, ODB path to the key used to set a value.

- set_key_index, index of an ODB set variable in case it is an array.

- set_key_value, new set value of the ODB variable.

- odb_readback_key_path, ODB path to a readback value to check if the command actually worked.

- readback_key_index, index of an ODB readback variable in case it is an array.

- timeout, within this given timeout (in sec) the readback value should have reached the set value, if not a warning will be generated and the next autorun command will be executed anyway.

- tolerance, tolerance needed to be reached (i.e. |set value - readback value| < tolerance) before the next command is executed.

Examples:

ODB_SET_DATA /Equipment/LED_Test/Variables/Output[1], 1

ODB_SET_DATA /Equipment/LED_Test/Variables/Output[0], 20.0, /Equipment/LED_Test/Variables/Input[1], 60, 0.05

ODB_SET_DATA "/Info/t0_Parameter/Leff RAon (mm)", 726

ODB_SET_DATA "/Info/Somthing Important", "string value of something important"

Description: With this command, ODB values can be manipulated directly. Since this is rather dangerous you should really understand what you are doing before using this command!

Comments: String based values must not contain any of the following signs: quotes, i.e. "", '<', and '>'

Set ODB arrays (FOR INTERNAL USE ONLY)

where value has to be of type 'float'.

Examples:

ODB_SET_DATA_ARRAY /Equipment/K2400/Variables/Output, 0, 1, 10, 1, 1, 1e-5, 1.5, 0, 1

Description: With this command, ODB arrays of type float can be set. It directly manipulates the online data base of the instrument and hence this is rather dangerous command you really should understand what you are doing before using it!

LEM Auto Run Sequence Example

Here follows a syntactically correct example:

Implementation Details of the LEM Auto Run Sequence

The LEM Auto Run Sequence (LARS) is set up the following way:

-

The user script is translated into a XML output-file (lets call it

lar_seq.xml) without any consistency checks. -

lar_seq.xmlis than parsed back with a validating schema parser (XERCES). Here any errors the user might have entered will be detected and fed back. - If the parsing was successful the whole user sequence is sequentialized and handed over to the autorun sequence loop.

The applied schema for the parsing process is given in the file lemAutoRun.xsd. The mapping between the above described user auto run commands and the corresponding xml-tags should be obvious.

Most of the routines are implemented in a straight forward fashion, however there are some which some additional background information will be given.

Implementation of Set Field

First it is verified that the corresponding client is indeed running, if not, it will stop the autorun sequence. This is a measure of precaution. In a next step the new field value is sent to the ODB, followed by a verification that the new field value is indeed reached. If it is not reached within a timeout given in the lemAutoRun.xml start-up file, an error is emitted and the autorun sequence stopped.

Implementation of Set Sample HV and Set Ring Anode HV

First it is verified that the corresponding client is indeed running, if not, it will stop the autorun sequence. This is a measure of precaution. In a next step the new HV value is sent to the ODB, followed by a verification that the value is indeed reached. If it is not reached within a timeout given in the lemAutoRun.xml start-up file, an error is emitted and the autorun sequence stopped.

Implementation of Set Sample Temperature and the Temperature Monitoring during a Run

There are 3 different regimes for the temperature change/monitoring:

- stable temperature

- increasing temperature

- decreasing temperature

They will be discussed separately in the following. It is worth mentioning that the TEMP command (see Set Sample Temperature (Cryos and Oven) ) is always either following the increasing- or decreasing temperature procedure and stable temperature is only check by itself during uSR data taking.

An important note: As you will read the set temperature command will try to operate the sliding valves between the chambers (BPVX/BPVY). However, it only operates these valves if they are initially open! The reason is that you might want to use the autorun sequence also for initial cooling of the sample, while growing a new moderator. In this case it would be fatal if the set temperature command would open the BPVX, etc. Therefore it is important that the user checks the valve states before starting any autorun and makes sure that the valves are in the state he/she wants. Anyway, to start a uSR run with a closed BPVX or BPVY will lead to a VERY low slow muon rate at the sample ;-)

If you plan to use the demand temperature ramping feature of the LakeShore 340, please read very carefully the following 3 subsections. Here the main reason why it has been introduced: when increasing the temperature, there will be also a pressure increase in the sample chamber due to degassing. This effect is most dramatic below 100K. If no demand temperature ramping is used, the pressure might increase to values > 1e-6 mbar. 1e-6 mbar is the critical pressure to fire the high voltage interlocks, which will stop the autorun sequence immediately! A second reason is that you cannot tolerate temperature overshooting in your experiment. If this is your case it would be wise to test the temperature part of your autorun sequence first to make sure that it really is doing as you expecting.

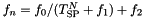

Stable Temperature

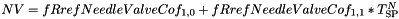

During a run, a temperature value is taken every 5 sec (at the moment hard-wired) and pushed into a ring history buffer. The history buffer is fitted to a parabola model which is used to adjust the He flow if necessary. This procedure should guarantee that the heater stays always in a sensible range. The formula to adjust the flow is

![\[ f_n = f_c \cdot \exp(p_H \left[ (h_c - h_p) + d_H h_T \right]) \]](form_0.png)

where  is the new flow,

is the new flow,  is the current flow.

is the current flow.  is

is

![\[ p_H = - p_H^0 - p_H^1 \cdot T_{\rm SP} \]](form_4.png)

with  the setpoint temperature.

the setpoint temperature.  is the current heater value.

is the current heater value.  is 50 for the heater range 3, 40 for the heater range 4, and

is 50 for the heater range 3, 40 for the heater range 4, and  for the heater range 5.

for the heater range 5.  is the first derivative of the parabolic model at current time.

is the first derivative of the parabolic model at current time.

The missing parameters are numbers collected with their XML startup file pendant here,

bh_flow_p_heat_0

bh_flow_p_heat_1

bh_flow_d_heat

If enabled, the transferline needlevalve will be adjusted according to the following rules:

-

If the Bronkhorst flow valve opening is larger then 0.9 then

If the realized flow is less then 20 % of the demandflow then

Else

-

If the pressure in the cryostat is more then 0.8 barr then set

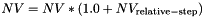

Increasing Temperature

When the setpoint is increased the following steps are taken:

- Close the BPVX sliding valve (between moderator- and trigger-chamber) to protect the moderator.

- If the new setpoint

is too large compared to the current one, precisely if

is too large compared to the current one, precisely if  (

(

max_temp_increasein the XML startup file), (i) the high voltages in the sample chamber (= Sample, Sample_G2, Sample_G1, RA-R, RA-L) are switched off, (ii) the valve between the sample- and the trigger-chamber (BPVY) is closed. - Set the flow according to the setpoint

, where the XML constants are

, where the XML constants are

bh_flow_temp,

bh_flow_temp_offset, and

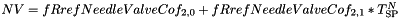

bh_flow_offset. - Set the needlevalve (if enabled) according to

for 0 < < 8 :

< 8 :

for 8 < < 10 :

< 10 :

for 10 < < 15 :

< 15 :

for 15 < < 350 :

< 350 :

- Set the setpoint on the sample LS340.

- If no PID's are given, the zone settings of the LS340 apply.

- Store the D value internally and switch it than to zero.

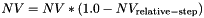

- If the condition

, where

, where  is the measured temperature and

is the measured temperature and

d_set_ratioin the XML startup file, reset D to its original value. - WAIT FOR STABILITY by calling PLemAutoRun::CheckTempStability() and PLemAutoRun::SampleTempConsiderFlow() periodically. The first routine is checking if the required stability is reached. The second routine decides if it is necessary to adjust the flow based on the heater history.

- When the stability is reached or the timeout fired, open the BPVY (only if it was initially open) and ramp the sample region HV's back if necessary.

- Open the BPVX sliding valve (between moderator- and trigger-chamber). This is only done, if the BPVX has been open at the beginning of the command, otherwise it will stay closed.

Decreasing Temperature

Decreasing temperature works the fastest, if demand temperature ramping (in the following called ramping) value is set to zero! It is still possible to use it but than you are on your one, concerning the time constant of the cooling down. Furthermore you need to consider the He flow by yourself since, if not given explicitly, the algorithm will just set the flow of the end demand temperature resulting in the predominant number of cases in cooling rates of < 1 K/min!

Here the following procedure is followed:

- Close the BPVX sliding valve (between moderator- and trigger-chamber) to protect the moderator.

- Check if demand temperature ramping is given:

- yes, set it

- no, set it to zero. This assures a time efficient cooling even when the user has forgotten to set it to zero. Still it is possible to use ramping is needed, just by explicitly setting it.

- Set the new setpoint of the LS340.

- If no PID's are given, the zone settings of the LS340 apply.

- Store the D value internally and switch it than to zero.

- If NO ramping is given

- Set the flow to 10000 for setpoints > 50K and 30000 for setpoints < 50K, respectively.

- Set needlevalve (if enabled) according to setpoint (see above).

- If the condition

, where

, where  is the measured temperature and

is the measured temperature and

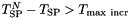

d_set_ratioin the XML startup file, reset D to its original value. - Start reducing the flow if getting close to the setpoint, precisely if

and

and  (

(

flow_set_ratioand

flow_set_absolute), reduce the flow to 1.5 times the final needed flow (see incr_temp). - Wait for

flow_timeout_reduction(sec) and than reduced to flow to 1.2 times the final needed flow. - Wait for

flow_timeout_reduction(sec) and than reduced to flow to 1.1 times the final needed flow. - Wait for

flow_timeout_reduction(sec) and than reduced to flow to the final needed flow.

- Else if ramping is given

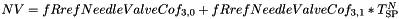

- Set needlevalve (if enabled) according to prevailing setpoint.

- Adjust the He flow according to the current demand temperature instead of the final demand temperature and take the rampspeed into account via the following equation:

![\[f_n = f_0 / T_{\rm SP}^N + f_1 + v_{ramp} * C_V * C_P\]](form_34.png)

where is the rampspeed in K/sec,

is the rampspeed in K/sec,  is the heat capacity in Joule/K and

is the heat capacity in Joule/K and  is the cooling power of the flow in Bronkhorst units (

is the cooling power of the flow in Bronkhorst units (  ) / Watt.

) / Watt.

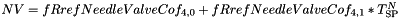

If is the prevailing setpoint, than the heat capacity is calculated from

is the prevailing setpoint, than the heat capacity is calculated from

![\[C_V = fHeatCapCof1 * T_set + fHeatCapCof2 * T_set^2 + hHeatCapCof3 * T_set^3\]](form_40.png)

and the cooling power is obtained via

![\[C_P = fDFlowDp0 + fDflowDp1 * exp( fDflowDpExp * log(T_set)\]](form_41.png)

- If the condition

, where

, where  is the measured temperature and

is the measured temperature and

d_set_ratioin the XML startup file, reset D to its original value.

- WAIT FOR STABILITY by calling PLemAutoRun::CheckTempStability() and PLemAutoRun::SampleTempConsiderFlow() periodically. The first routine is checking if the required stability is reached. The second routine decides if it is necessary to adjust the flow based on the heater history.

- Open the BPVX sliding valve (between moderator- and trigger-chamber). This is only done, if the BPVX has been open at the beginning of the command, otherwise it will stay closed.

Implementation of Set Run Title

As described in Run Title, the user can include some specific tags, which are than replaced by their values from the ODB. The question is: when is this done? It is actually done when the command is executed, i.e. the run title should almost always been placed directly before a run start command (Run Start Command)

Description of the XML Startup Files and the Parameters

The lemAutoRun uses two startup XML files to obtain most of the essential parameter for operation. The first one (lemAutoRun.xml) is a global one, holding all the informations which are independent of the sample cryostat in use, whereas the second one depends on the sample cryo, holding all its necessary parameters. The names for the sample cryo XML files are:

lemAutoRun_KontiCryo1.xmlfor the Konti-1lemAutoRun_KontiCryo2.xmlfor the Konti-2lemAutoRun_KontiCryo3.xmlfor the Konti-3lemAutoRun_LowTemp1.xmlfor the LowTemp-1 (former Mango)lemAutoRun_LowTemp2.xmlfor the LowTemp-2 (former Lemon)

The master XML files, i.e. the ones which are in the repository, are found under $MIDAS_WORK/lemQt/lemAutoRun/src. If a permanent change is needed they should be changed there and the corresponding file(s) should be submitted to the repository. In order that they will be used, they have to be transferred to the XML working directory which is $MIDAS_WORK/bin/.lemXMLs.

In the header of this startup files there is a comment block explaining all the defined variables (except those which are obvious). Here only those variables which might needed to be tweaked are shortly explained.

max_temp_increase: If a temperature increase is greater than this number [in (K)], the HV's in the sample region will be shut down and the sliding valve between the trigger- and the sample-chamber (BPVY) will be closed while increasing the temperature.field_timeout: If the set field value is not reached within this period [in (sec)], an error messages will be generated and the autorun sequence stops.field_accuracy: This value is the necessary field precision needed [in (A) for the moment], before going on.hv_timeout: If the sample HV value is not reached within this period [in (sec)], an error messages will be generated and the autorun sequence stops.hv_accuracy: The required sample HV accuracy [in (kV)].bh_max_flow: maximal allowed operational He flow of the Bronkhorst flow meter.bh_min_flow: minimal allowed operational He flow of the Bronkhorst flow meter.bh_flow_p_heat_0: see Stable Temperaturebh_flow_p_heat_1: see Stable Temperaturebh_flow_d_heat: see Stable Temperaturebh_flow_temp: see Increasing Temperaturebh_flow_temp_offset: see Increasing Temperaturebh_flow_offset: see Increasing Temperatured_set_ratio: see Increasing Temperatureabs_max_temp_diff: used to decide if temperature stability during the run is OK [in (K), see also PLemAutoRun::SampleTempStable()].rel_max_temp_diff: required relative temperature stability during the run [see also PLemAutoRun::SampleTempStable()].max_temp_trend: The first derivative of the parabolic model needs to be smaller than this value in order that the stability criteria is fulfilled [in (K/sec), see also PLemAutoRun::SampleTempStable()].heater_min: allowed lower heater value of the LS340 [in (%)]heater_max: allowed lower heater value of the LS340 [in (%)]timeout_flow_set: timeout after which the flow setting is reconsidered [in (sec)].flow_factor: adjusting factor for the He flow [see also PLemAutoRun::SampleTempConsiderFlow()].flow_set_ratio: see Decreasing Temperatureflow_set_absolute: see Decreasing Temperatureflow_timeout_reduction: see Decreasing TemperatureflowLowestFlowToConsider: see Stable TemperatureflowMaxRelFlowDiffToConsider: see Stable TemperaturedFlowDp0: see Decreasing TemperaturedFlowDp1: see Decreasing TemperaturedFlowDpExp: see Decreasing TemperatureheatCapCof1: see Decreasing TemperatureheatCapCof2: see Decreasing TemperatureheatCapCof3: see Decreasing TemperatureneedleValveInUse>: see Stable TemperatureprefNeedleValveCof_1_0: see Decreasing Temperature and Increasing TemperatureprefNeedleValveCof_1_1: see Decreasing Temperature and Increasing TemperatureprefNeedleValveCof_2_0: see Decreasing Temperature and Increasing TemperatureprefNeedleValveCof_2_1: see Decreasing Temperature and Increasing TemperatureprefNeedleValveCof_3_0: see Decreasing Temperature and Increasing TemperatureprefNeedleValveCof_3_1: see Decreasing Temperature and Increasing TemperatureprefNeedleValveCof_4_0: see Decreasing Temperature and Increasing TemperatureprefNeedleValveCof_4_1: see Decreasing Temperature and Increasing TemperatureprefNeedleValveRelStep>: see Stable TemperatureprefNeedleValveAbsStep: see Stable Temperature

1.8.14

1.8.14